How Brands Are Using Bundles For Valentine’s Day Procrastinators

Below are a few of our favorite Valentine’s Day bundle examples we’ve already seen from brands using Simple Bundles.

Tina Donati

Dec 10, 2025 · 8 min

Nothing exposes weak operational foundations faster than bundled products.

Tina Donati

Dec 10, 2025 · 8 min

Tina Donati is the Head of Marketing at Simple Bundles and has spent the past 7+ years helping Shopify brands streamline their tech stack and unlock growth through smarter product bundling, better UX, and cleaner ops.

Every ecommerce brand hits a point where growth stops being about new campaigns or flashier content and becomes about something far less glamorous: operations.

And nothing exposes weak operational foundations faster than bundled products.

Which is ironic, because bundles are supposed to be the hero tactic. They lift average order value, drive profitable merchandising, improve retention, and make customers feel like they’re getting more value. Most brands don’t fail because the bundle concept is bad — they fail because the inventory management architecture behind the bundle was never built to support it.

This guide is not about creating bundles. It’s about making them work. The messy, operationally complicated, nobody-told-you-this-part work.

The kind that determines whether your ecommerce business can scale bundles without constant stockouts, operational chaos, or overspending on shipping.

Bundle inventory management is the process of ensuring that the items that make up a product bundle (its components) are tracked accurately across:

Effective bundle inventory management ensures that:

Poorly managed bundles create friction that grows exponentially as order volume increases — especially when your Shopify store is generating orders across multiple sales channels and pushing data through different systems.

When we speak to brands about bundling, the problems they describe almost always sound like this:

None of these are bundling issues. They are shopify sku architecture issues disguised as bundle problems, usually caused by the system treating each individual item differently across platforms.

The real root causes usually fall into three buckets:

Shopify does not calculate bundle inventory automatically. Instead, Shopify:

3PLs think in terms of:

If you don’t feed 3PLs the correct bundle components, they will:

A bundle is only in stock if all components are in stock in the same pickable location.

But many brands unknowingly:

Shopify sees this as: “Both components exist somewhere, so sure—the bundle is in stock.”

Your 3PL sees: “We can’t pick this from any single warehouse.”

The result? Split shipments, wrong shipping rates, or fulfillment failure.

It’s how everyone — Shopify, your 3PL, your team — knows exactly what the bundle is.

A real BOM includes:

Without a BOM, every system involved in fulfillment is forced to make assumptions. Assumptions are the primary cause of:

A well-maintained BOM is the backbone of any strong inventory management system and is essential for brands that want to optimize bundle operations.

Every bundle relies on one of three inventory models. Understanding the differences between them—and their implications—is essential for choosing the right operational strategy.

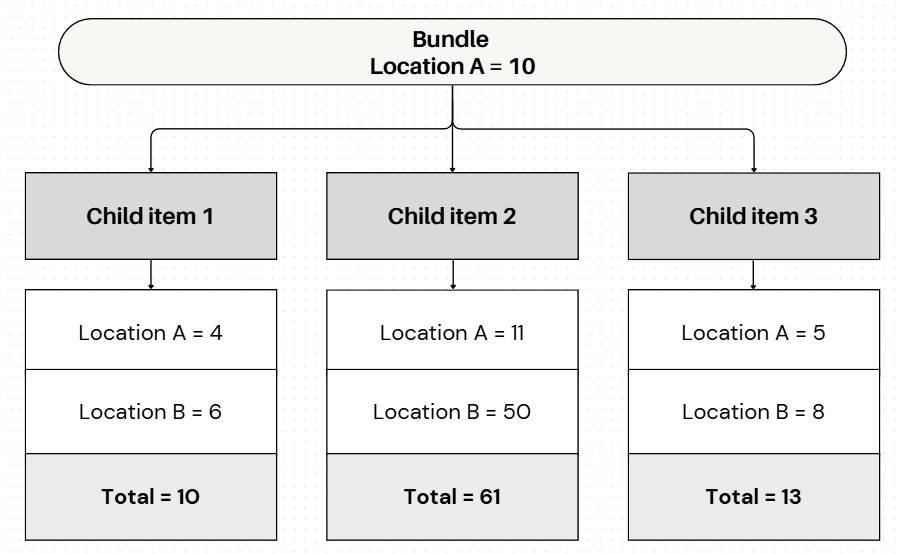

This model requires that all bundle components be available at the same fulfillment location. If even one component is missing, the bundle is considered unavailable.

Operational impact:

However, it can also lead to unexpected “out of stock” scenarios if components are unevenly distributed across locations. Brands with multiple fulfillment nodes often encounter this when the merchandising team assumes global availability but the warehouse operates within regional inventory constraints.

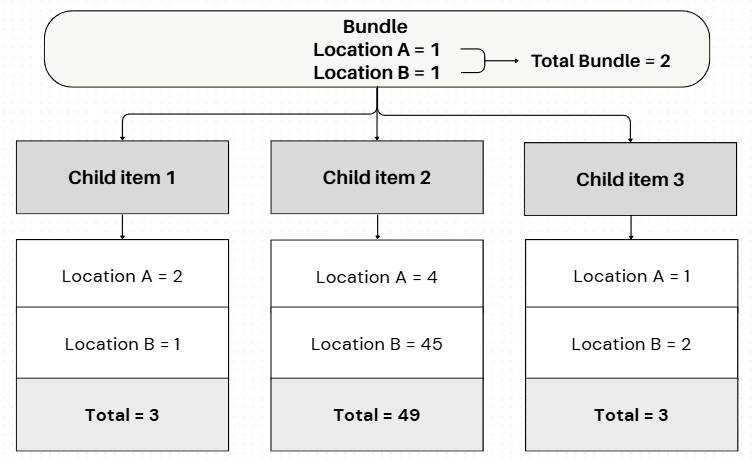

Pooled inventory expands bundle availability by using the combined total inventory of all components across all locations.

This model increases storefront sell-through but introduces risk:

Pooled inventory works best when shipping cost variance is low or when multi-node routing is tightly controlled.

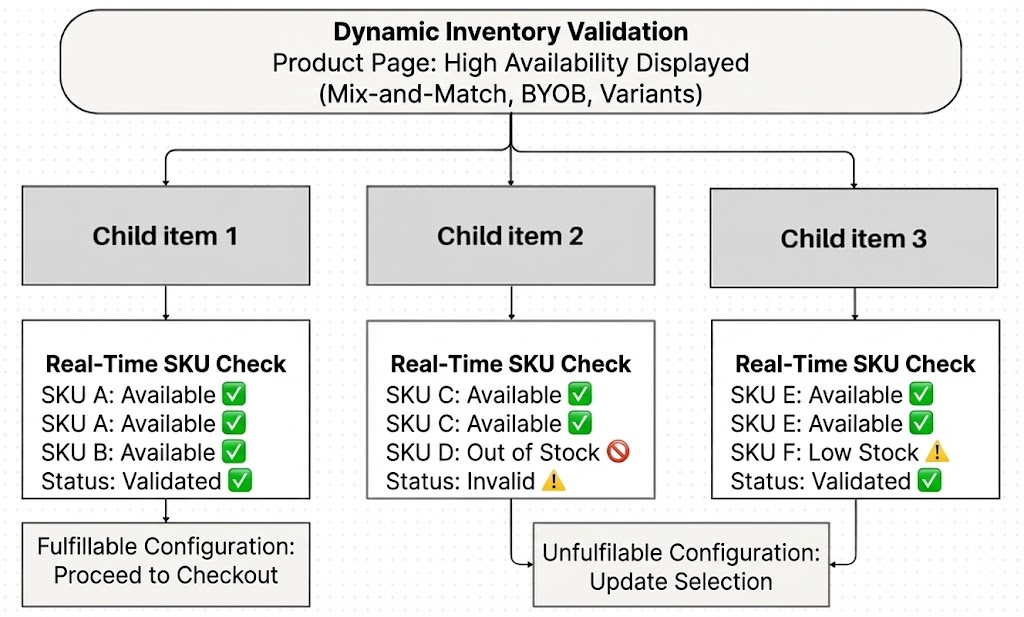

This model displays high bundle availability on the product page but validates SKU-level availability when the shopper builds a bundle or proceeds to checkout.

Dynamic validation is essential for:

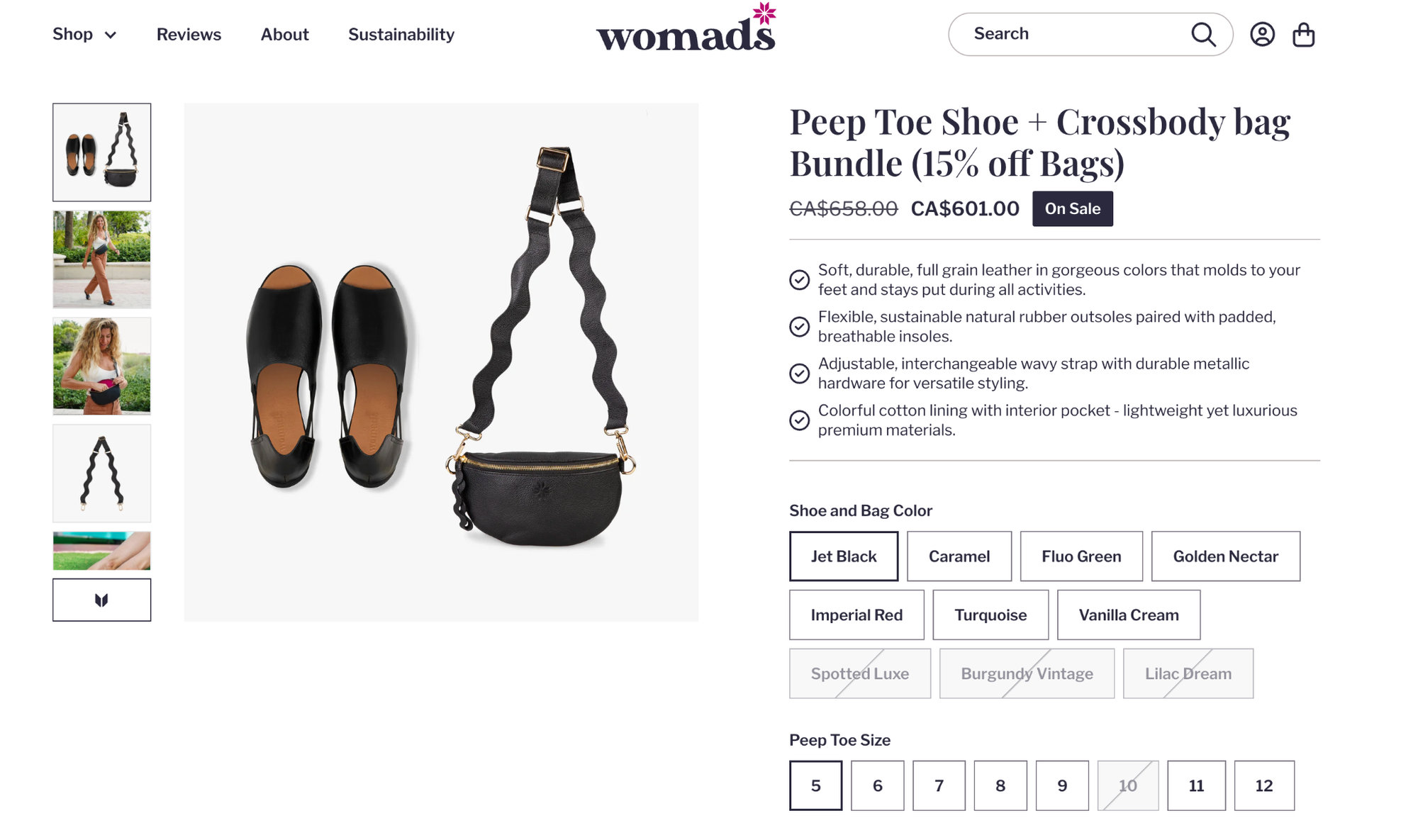

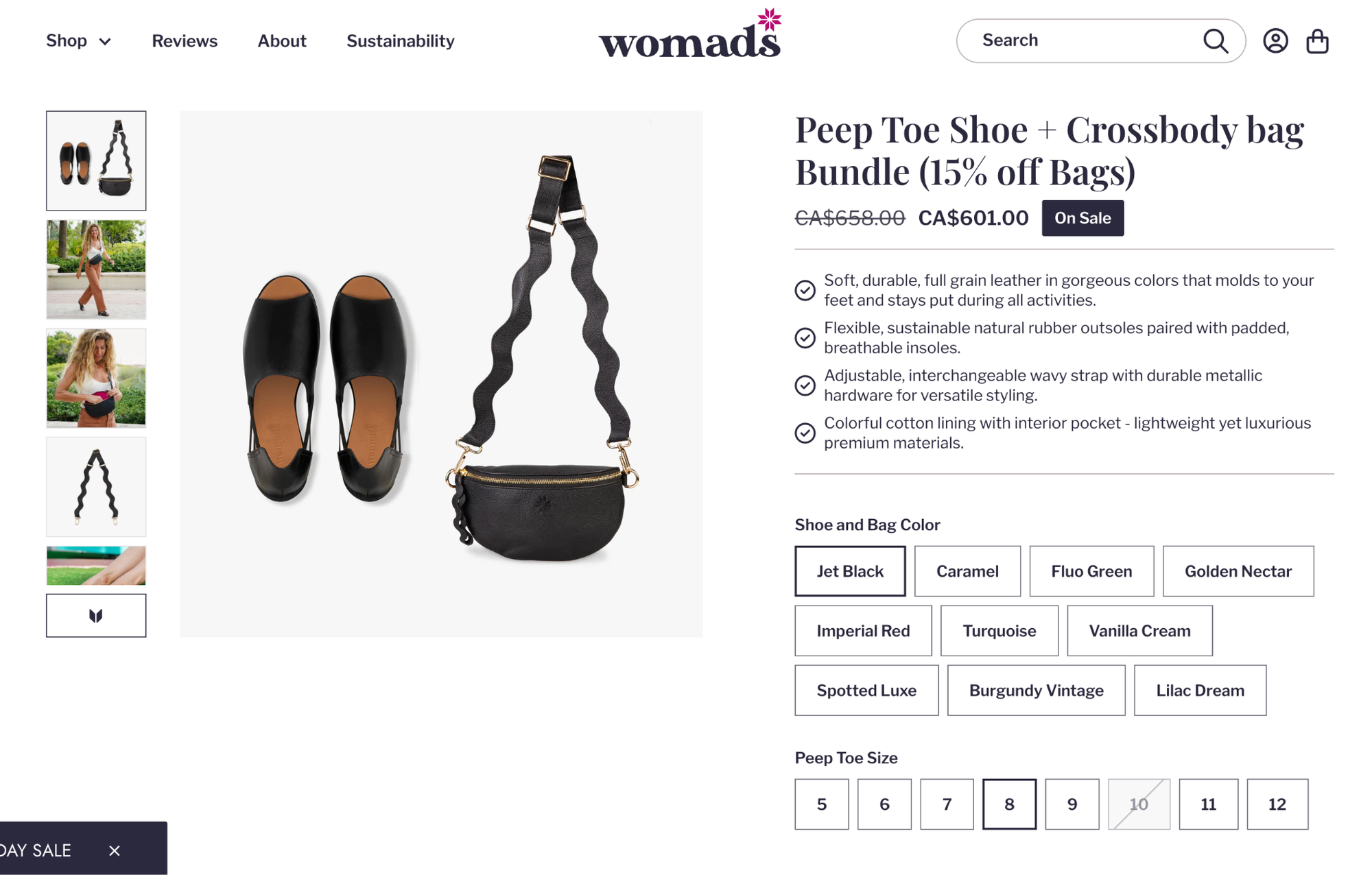

For example, you can see how this works with Womads, a sustainable shoe and bag brand. For this bundle, the size 5 shoes are out of stock for the colors “Spotted Luxe”, “Burgundy Vintage” and “Lilac Dream,” which marks the entire bundle out of stock to purchase.

But as soon as you change the shoe size to 8, these colors are now in stock and available to order:

Dynamic validation ensures only physically fulfillable configurations appear at checkout — critical when offering mix and match experiences or bundled items with many variations.

Once inventory is distributed across multiple locations, bundle inventory management becomes significantly more complex. A bundle is fulfillable only when all required components are present and pickable in the same location.

Common failure patterns include:

These discrepancies create downstream impacts such as split shipments, higher shipping rates, delivery delays, and increased customer service volume. Brands with distributed fulfillment must adopt explicit rules governing how bundles should route and under what circumstances they should be considered unavailable.

Bundles can be fulfilled in two ways, and choosing the right model is crucial for maintaining efficiency and accuracy.

Pick-to-order bundles are assembled at the time of fulfillment by selecting each component individually.

Advantages:

Risks:

Pick-to-order is most effective for low-volume bundles, customizable bundles, or those with frequently changing components.

Pre-kitted bundles are assembled in advance and stored as ready-to-ship units.

Advantages:

Risks:

Pre-kitting is ideal for high-volume bundles, gift sets, subscription shipments, and seasonal campaigns where predictability is essential.

Shipping for bundles is frequently miscalculated because Shopify’s shipping engine uses component-level data—weight, dimensions, and origin—to determine rates.

If bundle weight or component dimensions are inaccurate:

For bundles with mixed materials (glass, liquids, jars, boxed items), dimensional weight becomes particularly important. A bundle may appear visually compact but still exceed major carriers' dimensional thresholds.

Every bundle should undergo weight and dimensional verification — especially bundles with mixed materials like skincare kits or fragile single product inserts. This includes:

Accurate shipping profiles prevent margin erosion and maintain customer trust.

Bundles introduce complexity into return workflows because customers may want to return:

Brands must determine whether they will accept:

Each choice carries operational implications.

Warehouse teams must also be instructed on:

Consistent returns logic is essential to preventing long-term inventory drift.

Instead of attempting to force Shopify to behave like a warehouse system—or expecting a 3PL to understand Shopify’s digital configuration—Simple Bundles provides a structured way to align the two.

It works by creating a clear mapping between parent bundle SKUs and their component SKUs, ensuring that the warehouse always sees the actual items required while Shopify maintains the storefront experience merchants want.

Simple Bundles offers tools that formalize the essential elements of bundle inventory management:

1. Accurate SKU RelationshipsBundles are broken down into their component SKUs, allowing inventory to be deducted correctly regardless of where it’s stored or how many bundles are purchased.

2. Support for Different Inventory ModelsWhether a brand needs strict location-based inventory, flexible pooled inventory, or dynamic validation for customizable bundles, Simple Bundles can apply the right logic behind the scenes. This allows Shopify to display availability appropriately without overstating stock or creating fulfillment risk.

3. Clear Instructions for Fulfillment PartnersBecause Simple Bundles sends line-item detail to warehouses and 3PLs, pickers always know which items to pack. This eliminates the guesswork that often leads to missing items or incorrect shipments.

4. Predictable Shipping OutcomesBy enabling weight syncing and accurate mapping of component dimensions, Simple Bundles helps ensure that Shopify’s shipping engine reflects the true cost of shipping a bundle.

5. Return and Restocking SupportWith bundles represented as their component SKUs, returns are easier to process. Warehouse teams can restock items correctly, and refund logic becomes consistent with accounting and pricing rules.

Strong merchandising can make a bundle compelling, but only strong operations can make it profitable.

Bundle inventory management is the connective tissue that allows bundling to scale. It aligns digital storefront logic with physical fulfillment realities, ensuring that bundles are:

When inventory architecture, fulfillment workflows, and systems alignment are executed with intent, bundles move from being a revenue tactic to a reliable operational asset.

Try Simple Bundles free to clean up your bundle inventory and shipping workflows.